We work on:

- 3 axis milling machine CNC HAAS VF3YT

- 3 axis milling machine CNC HAAS VF2

- 3 axis milling machine CNC KLOPP KORRADI UW10 – 2pcs

- 3 axis milling machine MIKRON WF21-C - 2pcs

- 3 axis milling machine TOS KURIM - 2pcs

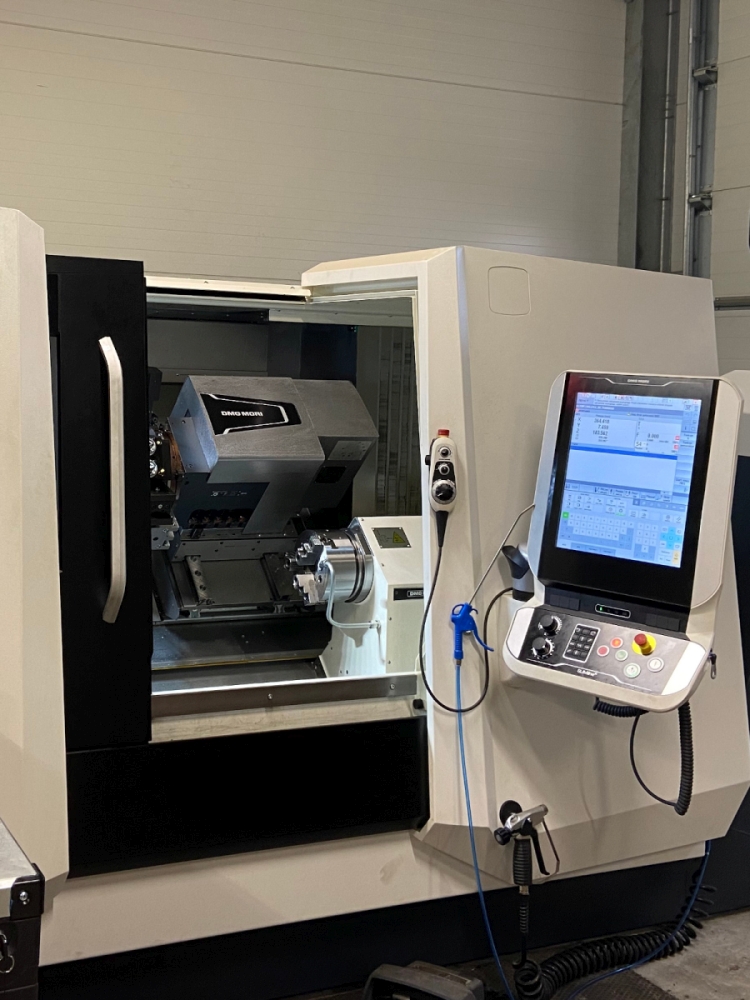

- 6 axis 2-spindles turning machine CNC DMG MORI CLX450

- 2 axis turning machinge CNC Bridgeport 1000

- manual turning maching - 2pcs

- Center grinding machine Jotes SWA 25

- Surface grinding machine

- Edm machine